The Digital Edition is Available

The Digital Edition is Available

Click the cover Image to Access the E-Magazine

PDCA and publishing partner

Lester Publications proudly announce that the

PileDriver magazine Issue #2-2022 is now available in digital format; watch your mailbox in coming days for your hard copy edition.

There is plenty of new content available in Issue #2; PDCA President

Brian Heck leads off the publication with his observations on a very active start to the year for the Association. Executive Director

Frank Peters follows with his insightful column about strides the organization is making on behalf of the driven pile industry.

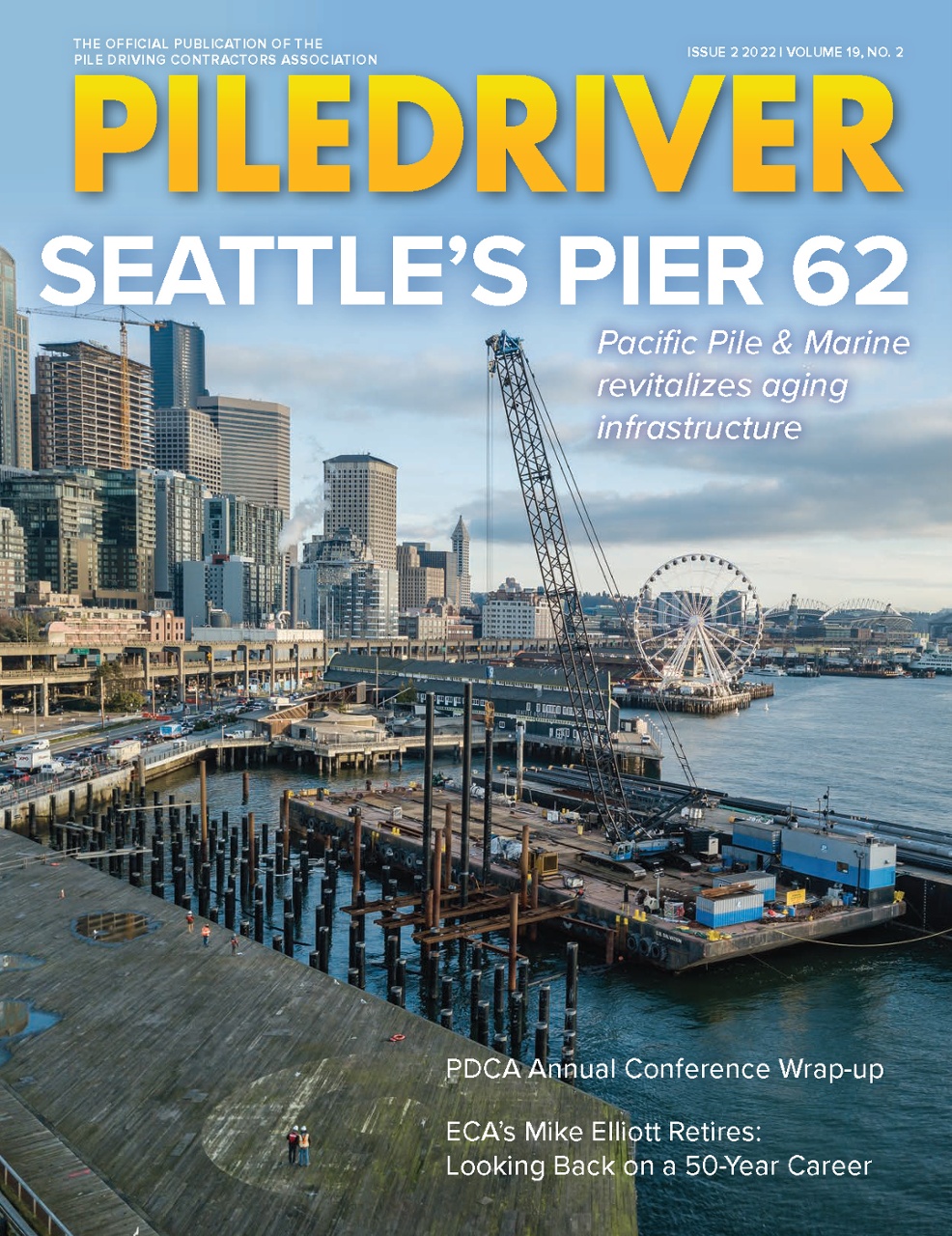

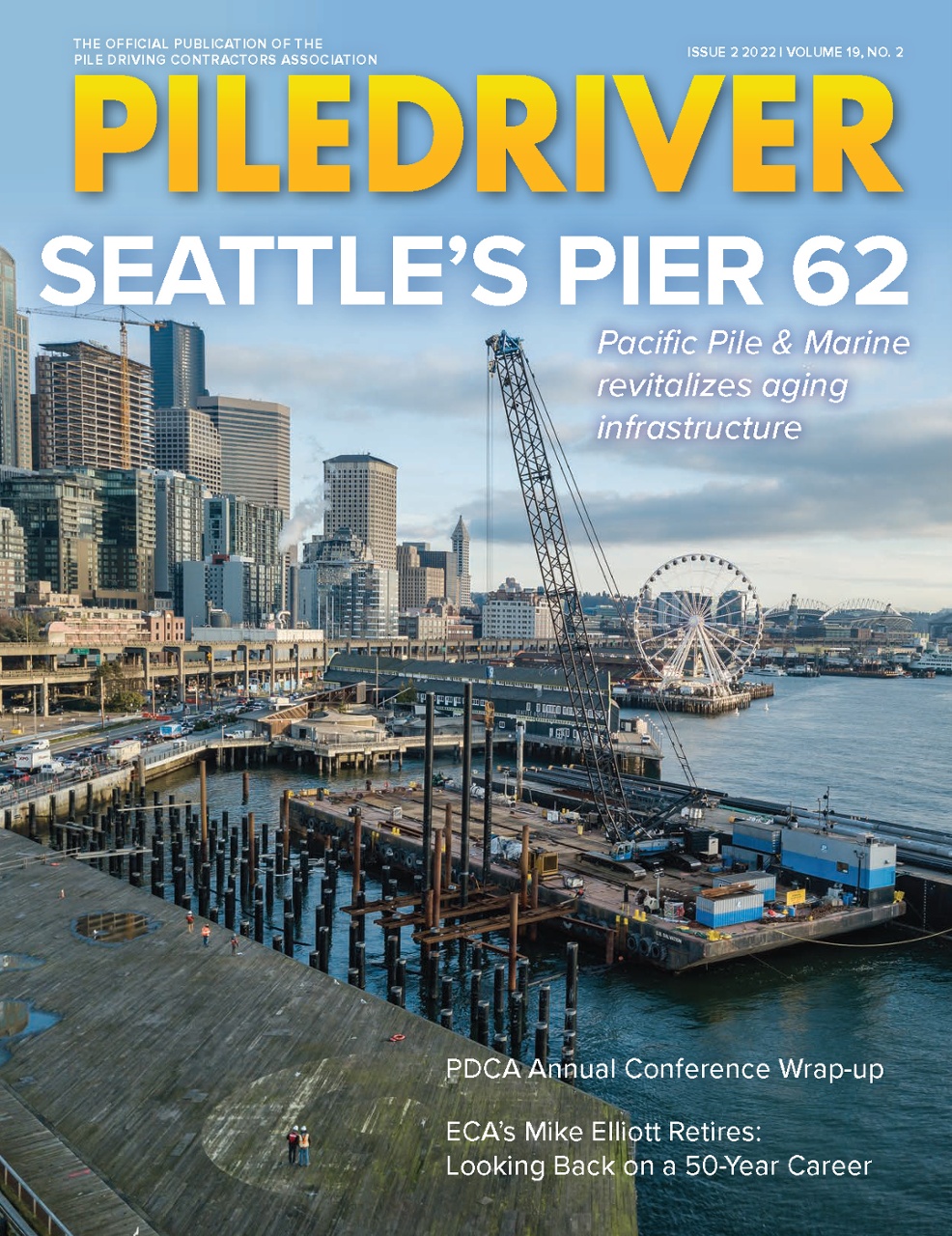

You will find fascinating project content when you read the cover story about

Seattle's Pier 62, a dramatic pile driving feat performed by

Pacific Pile & Marine. It creates a brand-new facade for the waterfront side of Downtown Seattle.

Don't miss a large section summarizing the PDCA Annual Conference which concluded in February. You will find plenty of photos from the various activities that took place throughout the week at the Arizona Grand Resort in Phoenix. Among them, PDCA Committee Meetings, Awards presentations and the golf outing.

It's been a remarkable career for

Mike Elliott who recently retired from

Equipment Corporation of America. A longtime friend to PDCA, Mike sat down with us to share his observations from a 50-year career in the pile driving industry. You will see some of the special photos taken at a recent company event honoring his contributions.

Check in on the PDCA Chapter news, notable headlines from the industry and a Business contribution from

Harris May of the

Dafanie Financial Group submits an article that provides guidance to employers on Worker's Compensation.

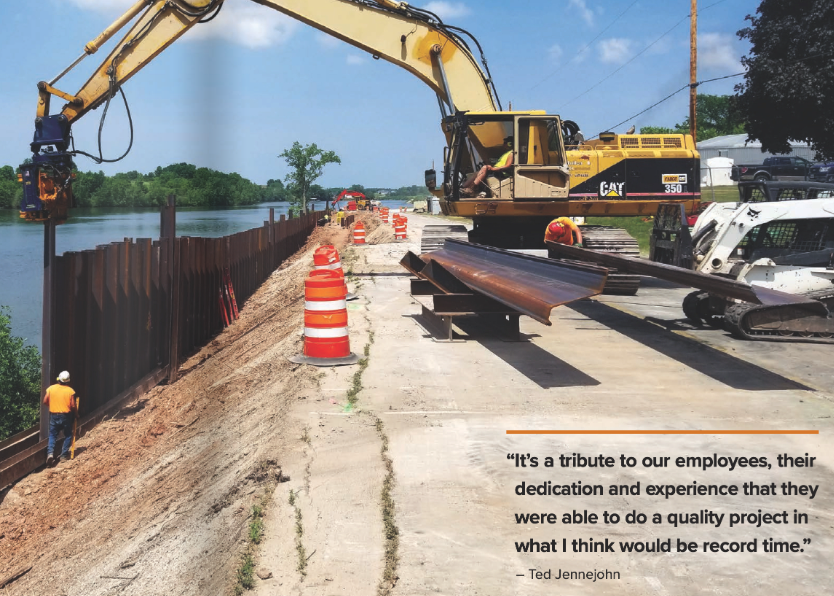

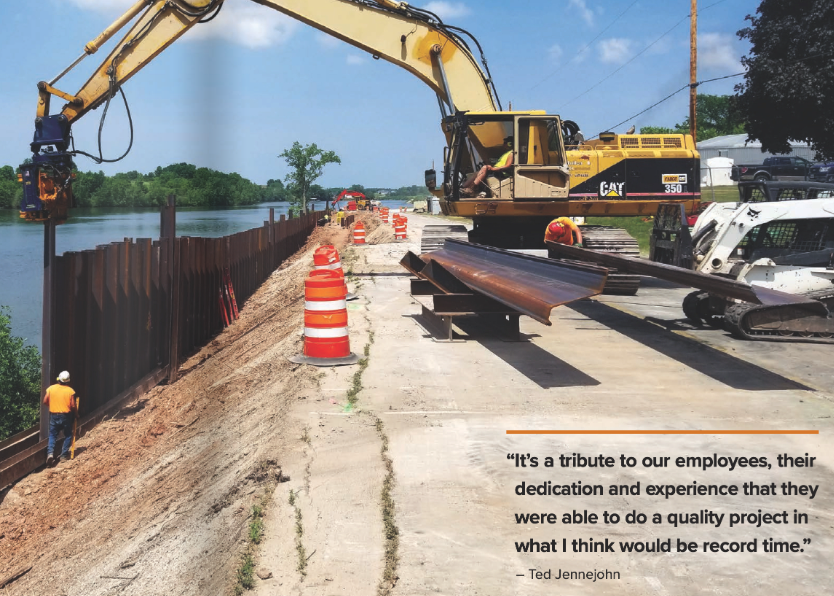

And don't miss Member profiles on

Farrell Brothers Marine Construction,

South Shore Pile Driving and

McMullen & Pitz. California attorney

Mark J. Rice (pictured) submits this issue's legal column.

South Shore Pile Driving LLC

|

McMullen & Pitz Construction Company |

Farrell Brothers Marine Construction, Inc. |

The Digital Edition is Available

The Digital Edition is Available